Pre-engineered Building Structures

(PEB) Pre Engineered Building is a concept of structure having high structural strength, economical design while it supersedes the conventional fabrication, it lowers down the stress of foundation, hence there is less cost on civil construction as well.

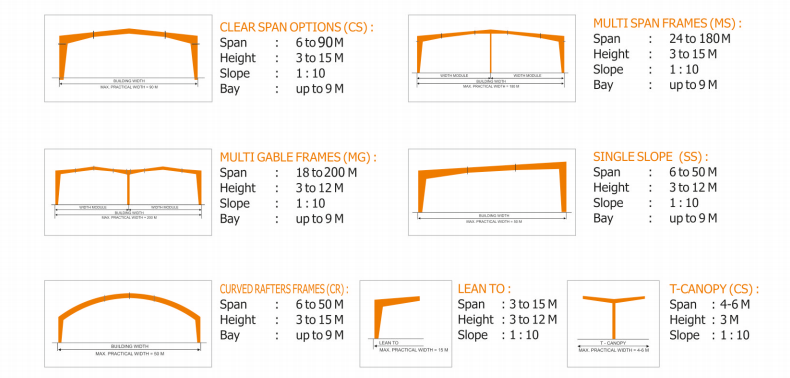

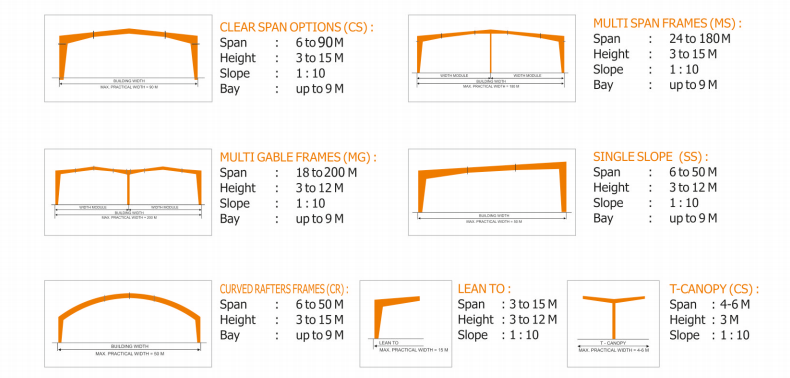

Tailor made buildings based on client’s requirement and actual design calculations using tapered sections. An efficiently designed Pre Engineered Building (PEB) can be lighter than the conventional steel building by up to 30%.

North Bengal Roof & Metal is well equipped to produce Pre-Engineered Buildings (PEB structure) as per client’s requirements. The company has all the latest machinery to support this segment. The entire design of Columns, Rafters and other Accessories is based on international structural standards and invoice high technical welding and quality production.

These are the PEB structures basically manufactured/fabricated at the factory with the high tensile steel material by collecting complete information of shed/building (viz: Length, Width, Height etc.)

Pre-Engineered Buildings (PEBs) offer several advantages:

Pre-Engineered Buildings (PEBs) are typically more cost-effective compared to traditional construction methods because they involve less material wastage, faster construction time, and easier assembly.

Pre-Engineered Buildings (PEBs) are designed and manufactured off-site, which reduces construction time significantly. This can be especially advantageous for projects with tight deadlines or in areas where weather conditions can delay traditional construction.

Pre-Engineered Buildings (PEBs) offer a high degree of design flexibility, allowing for customization according to specific project requirements. This flexibility includes the ability to incorporate various architectural features and accommodate future expansions or modifications.

Pre-Engineered Buildings (PEBs) are designed to optimize structural efficiency, minimizing material usage while maximizing strength and durability. This can result in lighter building structures, reducing foundation requirements and overall construction costs.

Pre-Engineered Buildings (PEBs) are manufactured in controlled factory environments, ensuring high-quality standards and consistency in materials and construction processes. This results in fewer defects and higher overall quality compared to on-site construction.

Pre-Engineered Buildings (PEBs) can incorporate energy-efficient features such as insulation, daylighting, and renewable energy systems more easily compared to traditional buildings. This can lead to lower energy consumption and operating costs over the lifetime of the building.

Pre-Engineered Buildings (PEBs) are typically designed for easy maintenance, with durable materials and simple construction techniques that facilitate regular upkeep and repairs.

Pre-Engineered Buildings (PEBs) can be designed to meet various sustainability standards, including LEED certification, by incorporating eco-friendly materials, efficient design principles, and energy-saving technologies.

Since most of the construction work for PEBs is done off-site, there is minimal disruption to the surrounding environment during the assembly process. This can be particularly beneficial in urban areas or locations with sensitive ecosystems.

Application For PEBs

North Bengal Roof & Metal provide the following applications for PEBs

-

Warehouse

-

Multi Storey Building

-

Rice Mills

-

Flour Mills